Turnkey Solution for New Energy Intelligent Equipment

With the rapid development of the new energy vehicle industry, the performance and safety of battery modules, as the heart of electric vehicles, are increasingly receiving high attention from the industry. In the manufacturing process of battery modules, the cell gluing/coating station is a crucial process that not only affects the overall structural strength and sealing of the battery module, but is also directly related to the safety performance and service life of the battery. This article aims to explore the key role and importance of the cell gluing/coating station in battery module production.

1. Enhance the structural strength of the module

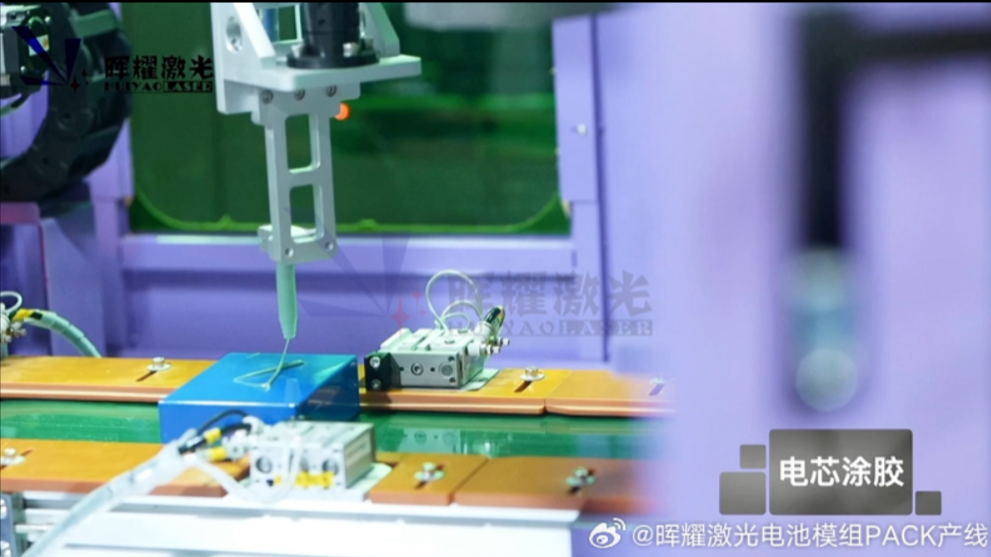

One of the main functions of cell gluing/coating is to significantly enhance the overall structural strength of the battery module by forming a strong bonding layer between the cell and the module frame or other cells. This layer of glue can absorb and disperse the vibration and impact force that may be generated during the use of the module, prevent relative movement between cells, and thus maintain the stability and integrity of the module structure. This is crucial to ensure the stable operation of the battery module under various complex working conditions.

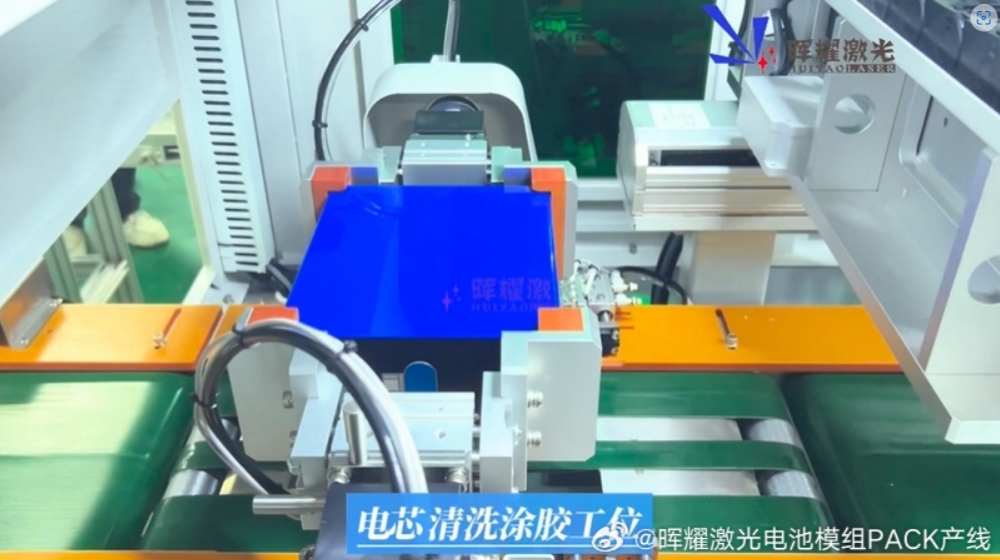

2. Improve sealing performance

In battery modules, good sealing is the key to preventing the intrusion of external impurities such as moisture and dust, as well as preventing electrolyte leakage. The battery cell gluing/coating station ensures an effective sealing barrier between the battery cell and the module shell by precisely controlling the amount and position of glue applied. This not only protects the battery cell from the influence of the external environment, but also avoids safety hazards such as short circuits and fires caused by electrolyte leakage, significantly improving the safety performance of the battery module.

3. Optimize thermal management

Batteries generate a lot of heat during operation. If it cannot be dissipated in a timely and effective manner, it will seriously affect the performance and life of the battery, and even cause safety accidents. The glue material used in the battery cell gluing/coating station often has a certain thermal conductivity, which can promote heat conduction between battery cells and between battery cells and module casings to a certain extent, and help optimize the thermal management system of the battery module. By reasonably designing the layout and type of glue, the heat dissipation efficiency of the battery module can be further improved to ensure that the battery operates within the optimal temperature range.

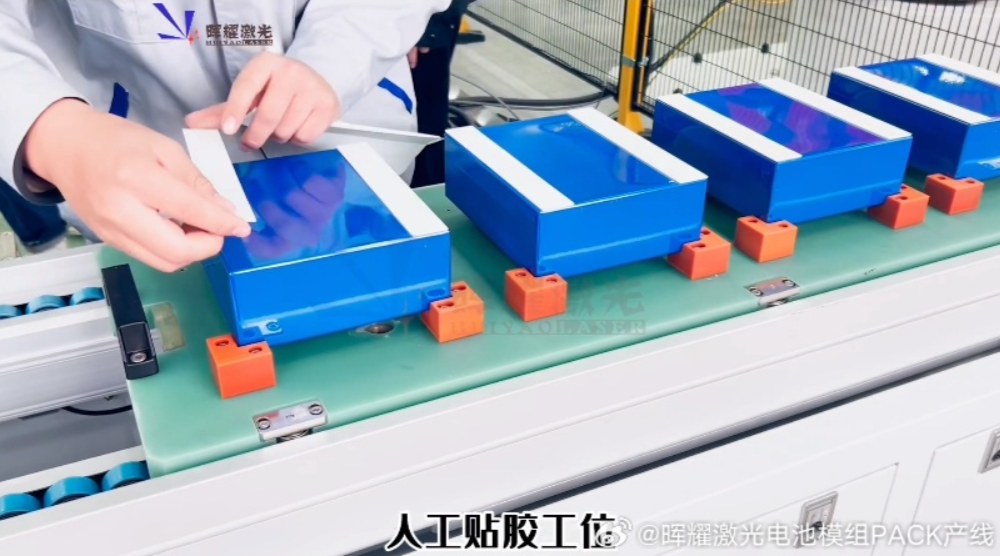

4. Improve production efficiency and automation level

With the continuous advancement of intelligent manufacturing technology, the battery cell gluing/coating station is gradually developing towards automation and intelligence. Automated gluing/coating equipment can accurately control the amount, speed and position of glue, reduce human errors and improve production efficiency. At the same time, through close integration with other links of the production line, the entire production process can be automated, further improving the overall efficiency and quality consistency of battery module production.

5. Conclusion

In summary, the cell gluing/coating station plays a pivotal role in the production of battery modules. It not only enhances the structural strength of the module and improves the sealing performance, but also optimizes the thermal management system and promotes the improvement of production efficiency and automation level. With the continuous development of new energy vehicle technology, the requirements for battery module performance will become higher and higher. Therefore, continuously optimizing the cell gluing/coating process and improving the performance and stability of glue materials will be an important research direction in the field of battery module manufacturing in the future.

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.