Turnkey Solution for New Energy Intelligent Equipment

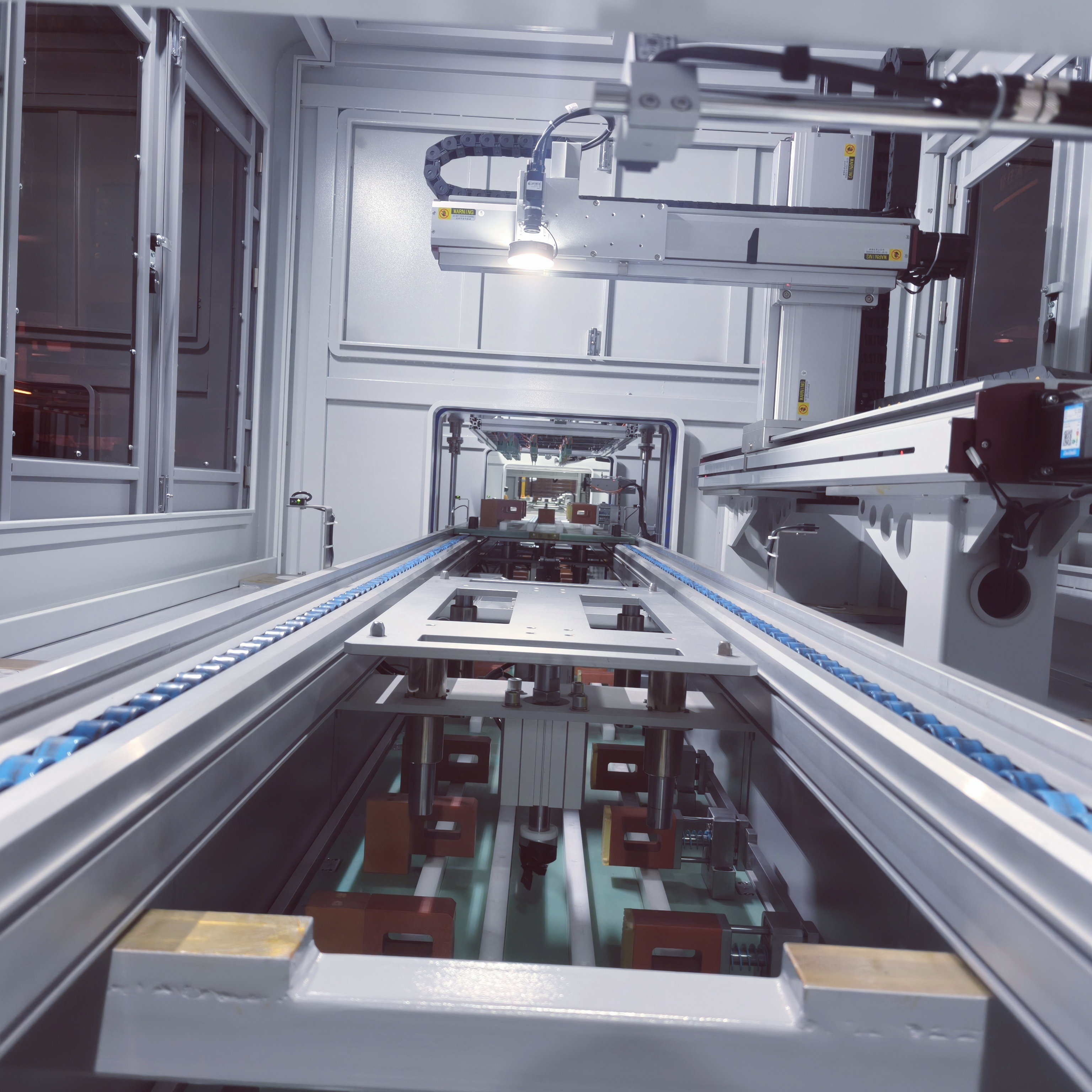

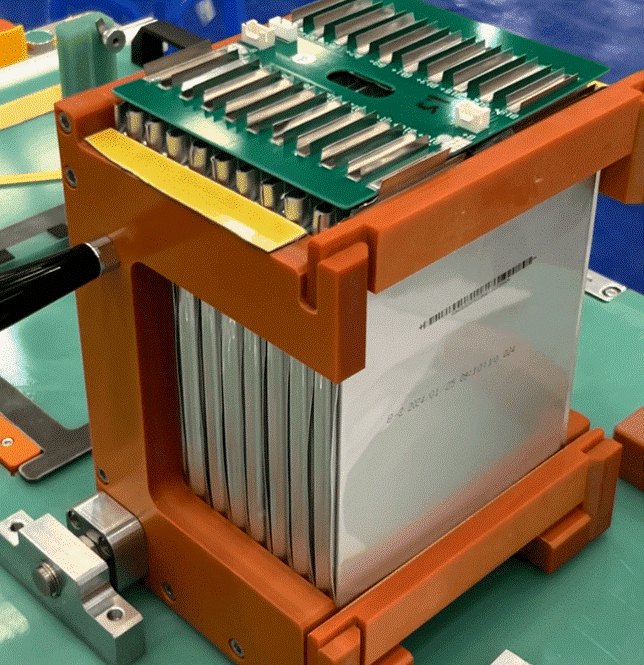

Pouch Battery Module Pack Assembly Line

Huiyao Laser is a leading manufacturer of pouch battery module pack assembly lines, providing end-to-end solutions for the automated production of pouch battery modules and packs. (1)Equipment capacity: ≥10PPM; (2)The final excellent rate is ≥99.8% (only the bad products caused by the equipment); (3)Equipment failure rate ≤ 2%; (4)Compatible with a variety of size module specifications, quick change. Laser output power stability (fluctuation) ≤±1%, the focal length of the galvanometer can be digitally displayed and adjusted, the range is -5.0~+5.0mm, and the adjustment accuracy is ≤0.5mm;(5)The welding track is edited by welding software, the welding process is automated, the parameters can be modified, and the operation and modification authority can be set.

Learn More

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Learn More

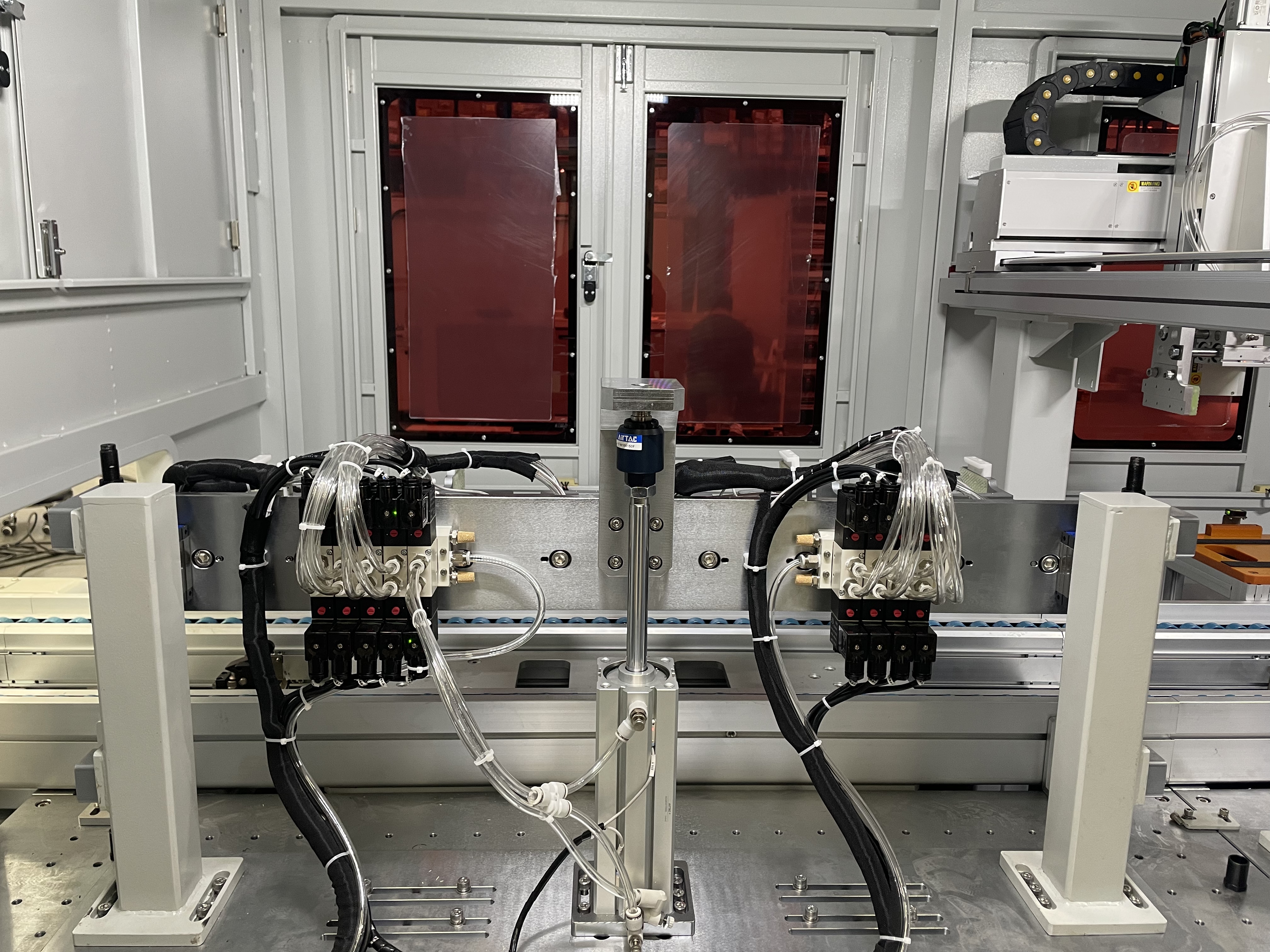

EPrismatic Battery Helium Leak Detection Equipment

Equipment Dimensions: Length: 2000 mm Width: 1500 mm Height: 1800 mm Weight: 1200 kg ± 5% Frame Material: High-strength steel with anti-corrosion coating. Worktable Material: Stainless steel with anti-static properties. Test Chamber Size: Length: 50–300 mm Width: 50–200 mm Height: 5–100 mm (adjustable).

Learn More

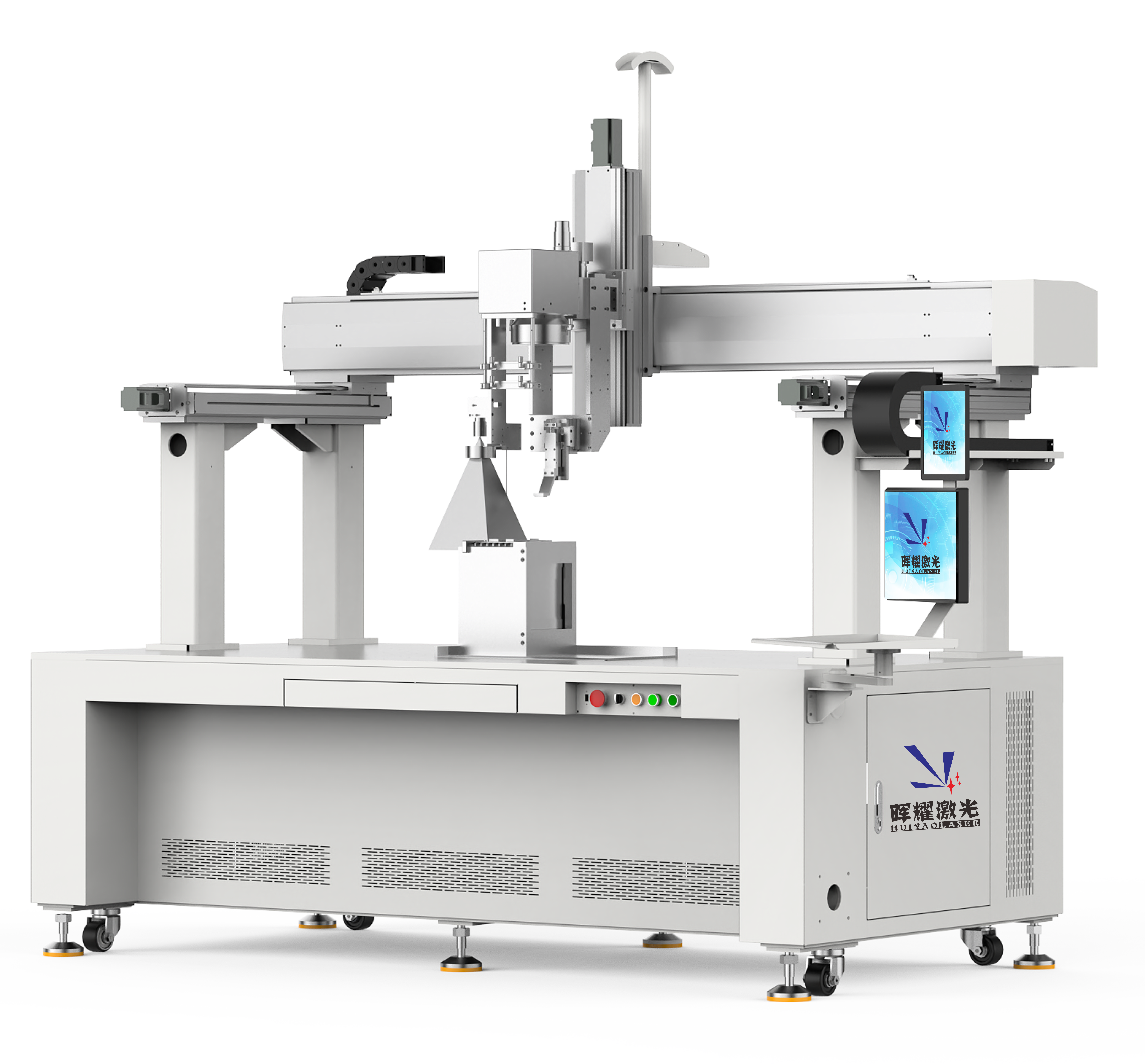

Automatic Explosion-Proof Valve Welding Machine

Equipment Name: Automatic Explosion-Proof Valve Welding Machine Model: HY-EPVW300 Application: Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards. Production Capacity: 20–30 valves per minute.

Learn MoreHuiYao Laser Technology (Luoyang)Co.,Ltd.(AKA YaoLaser)

Leading manufacturer of new energy intelligent equipment in the industry, dedicated to providing innovative customized solutions for Battery Module PACK Assembly Lines across various sectors. Since our establishment in 2019, Huiyao Laser has been consistently driving the development and application of laser technology, offering our customers high-quality, high-performance laser equipment, and automation production lines for battery module PACK assembly.

We cover an area of 10800 square meters

We serve 20+ countries and regions

Professional team provides 24h service

In the future, HuiYao Laser Technology will continue to uphold the core values of "service first, quality first, innovative development, and common growth," ontinuously increase its technology investment and innovation efforts, provide customers with even better laser equipment automation solutions, become a leader in the industry, and achieve sustainable and healthy development for the company.

View Details >>

What is Pole Laser Cleaning?

YAOLASER's pole laser cleaning technology revolutionizes surface cleaning for metal poles, pipes, an...

2025-08-09

What is Energy Storage Module Laser Welding?

Energy storage module laser welding is a precision welding technique used to assemble the structural...

2025-05-20

The Advantages of Annular Laser Welding Technology

The Advantages of Annular Laser Welding Technology With the rapid growth of the new energy vehicle ...

2025-05-20

What Are Pouch Cells? The Flexible Battery Technology Explained

What Are Pouch Cells? The Flexible Battery Technology Explained Imagine a battery that's...

2025-08-01

What is Battery Cell to Module Testing?

What is Battery Cell to Module Testing? Battery cell to module testing refers to a ser...

2025-07-29

What is Module Insulation Photo Cleaning?

What is Module Insulation Photo Cleaning? Module insulation photo cleaning refers to a preci...

2025-05-20

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.