Turnkey Solution for New Energy Intelligent Equipment

With the rapid growth of global demand for new energy, the new energy industry has become the core engine in the field of sustainable development. The widespread application of electric vehicles, energy storage systems, etc. has driven huge demand for efficient and stable batteries. As a key component of battery modules, their production methods and efficiency determine the competitiveness of the entire industry. So, what are battery modules and their production lines? What are the unique advantages of automated production lines?

1. Battery demand under the new energy wave

Countries around the world are actively promoting the application of new energy to cope with climate change and reduce the pressure of carbon emissions. Electric vehicles are gradually replacing fuel vehicles, clean energy sources such as wind energy and solar energy are rapidly becoming popular, and batteries, as the core technology for energy storage and drive, are experiencing rising demand. Against this background, battery module production has become an important link in ensuring the smooth development of the new energy industry, and it is particularly important to promote efficient and safe battery module production technology.

2. Battery module: the core unit of the battery pack

A battery module is a functional unit composed of multiple cells connected in series or parallel, and is mainly used to meet specific voltage and capacity requirements. As the basic component of battery packs, battery modules are widely used in electric vehicles, energy storage systems and other fields. It must not only have superior energy storage and output performance, but also must have a high degree of safety, especially in high-temperature or high-pressure environments to avoid potential safety hazards.

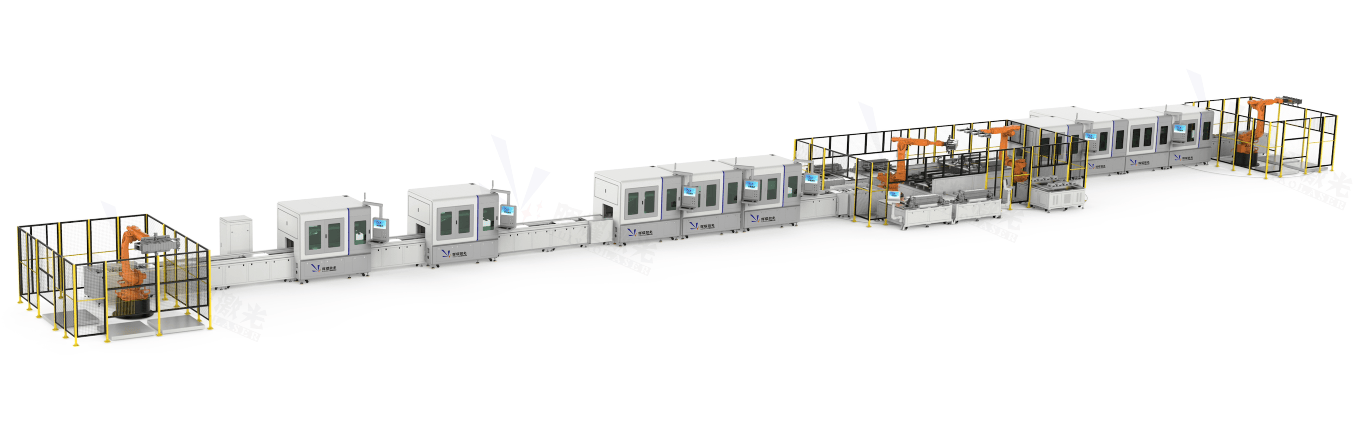

3. Battery module production line: guarantee of efficient manufacturing

The battery module production line is a systematic production process that assembles battery cells into battery modules through automated equipment and processes. The entire production process includes battery cell screening, assembly, laser welding, insulation treatment, testing and other steps to ensure that each battery module can meet high quality requirements. Today's battery module production lines mostly use automation technology to cope with growing production demands and strict product quality requirements.

4. Unique advantages of automated production lines

Automated production lines have the following significant advantages in battery module manufacturing:

1. Production efficiency is greatly improved: the automated system can work continuously, reducing downtime and improving production rhythm, thereby meeting the needs of large-scale production.

2. Significant reduction in labor costs: Automated equipment reduces reliance on manual operations, which not only reduces labor costs, but also reduces risks caused by human errors.

3. Product quality is more stable: For example, laser welding technology can accurately and stably complete the key connection work of battery modules, ensuring the quality consistency and safety of each module.

4. Flexible production to adapt to market changes: Automated production lines are highly flexible and can quickly adjust production according to different product needs to adapt to diversified markets and personalized customization needs.

5. Conclusion: Purchase automated module production lines to reduce costs and increase efficiency

In the context of the rapid development of new energy, purchasing an efficient and reliable automated battery module production line can not only help companies significantly reduce production costs, but also improve production efficiency and product quality. Keeping up with the trend of industry development and choosing advanced automated production equipment will be the key for enterprises to gain a foothold and develop in the new energy era.

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.