Turnkey Solution for New Energy Intelligent Equipment

Huiyao Laser is a leading manufacturer of pouch battery module pack assembly lines, providing end-to-end solutions for the automated production of pouch battery modules and packs. (1)Equipment capacity: ≥10PPM; (2)The final excellent rate is ≥99.8% (only the bad products caused by the equipment); (3)Equipment failure rate ≤ 2%; (4)Compatible with a variety of size module specifications, quick change. Laser output power stability (fluctuation) ≤±1%, the focal length of the galvanometer can be digitally displayed and adjusted, the range is -5.0~+5.0mm, and the adjustment accuracy is ≤0.5mm;(5)The welding track is edited by welding software, the welding process is automated, the parameters can be modified, and the operation and modification authority can be set.

Categories: Lithium Battery PACK Assembly REQUEST FOR QUOTE > TURN BACKHuiyao Laser is a leading manufacturer of pouch battery module pack assembly lines, providing end-to-end solutions for the automated production of pouch battery modules and packs. Our advanced assembly lines are designed for high precision, efficiency, and scalability, serving industries such as electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of pouch battery modules.

With expertise in prismatic battery manufacturing, Huiyao Laser offer tailored solutions to meet diverse production needs, ensuring superior quality, safety, and performance.

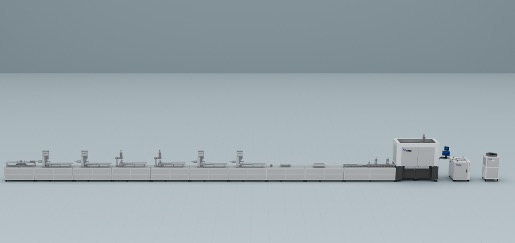

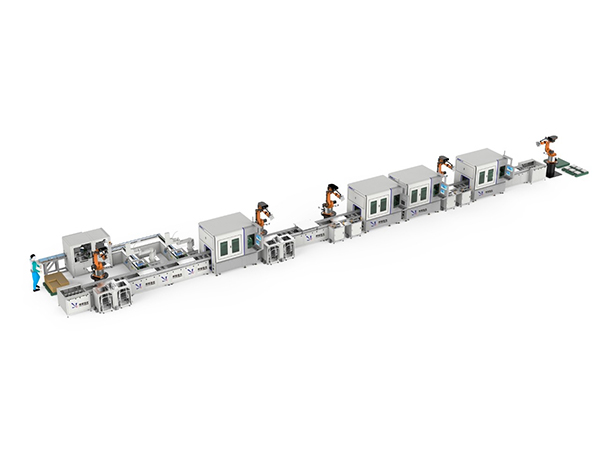

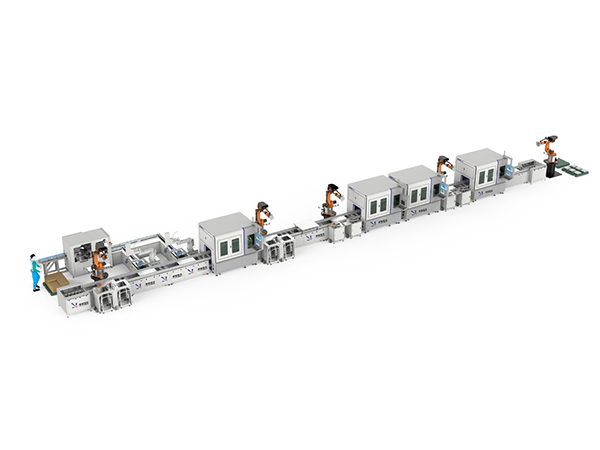

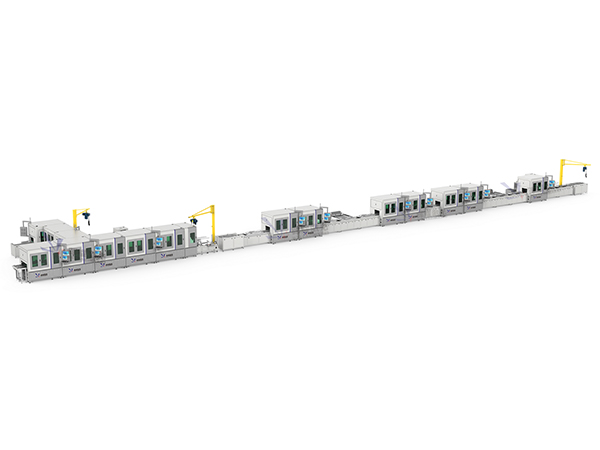

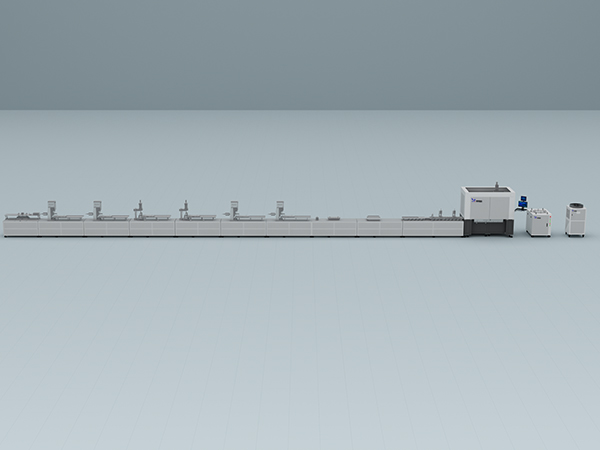

Pouch Battery Module PACK Assembly Line

Pouch Battery Module PACK Assembly Line Equipment List

| Workstation | Model Specification | Quality |

|---|---|---|

| Heat Conduction Plate Loading | Huiyao Customized | 1 |

| Terminal Tab Cutting Inspection | Huiyao Customized | 1 |

| Cell Loading | Huiyao Customized | 1 |

| Cell Glue Applying | Huiyao Customized | 1 |

| Terminal Tab Bracket Assemblying | Huiyao Customized | 1 |

| Cell Insulation Testing | Huiyao Customized | 1 |

| Unit Glue Applying | Huiyao Customized | 1 |

| Module Stacking | Huiyao Customized | 1 |

| Busbar Installation | Huiyao Customized | 1 |

| Terminal Tab Bending | Huiyao Customized | 1 |

| Terminal Tab Flatting | Huiyao Customized | 1 |

| NG Cell Re-work | Huiyao Customized | 1 |

| Insulation Testing | Huiyao Customized | 1 |

| Laser Welding | IPG/Raycus | 1 |

| Post-Welding Testing | Huiyao Customized | 1 |

| Insulation&Voltage Double-Sided Detection | Huiyao Customized | 1 |

| Sense Lead Insulation | Huiyao Customized | 1 |

| EOL Testing | RePower | 1 |

| Module Off-Loading | Huiyao Customized | 1 |

Pouch Battery Module PACK Assembly Line Techspecs

| Technical Specification | Technical Parameter | Remarks |

|---|---|---|

| Line Efficiency | ≥12PPM | Adjustable based on configuration |

| Production Line Dimension | 60000mm*8500mm*3500mm(L*W*H) | Adjustable based on workstation layout |

| Final Yield Rate | ≥99.8% | |

| Line Failure Rate | ≤2% | |

| Appearance Color | Custom | |

| Inspection Capability | Welding quality, voltage, internal resistance, temperature, etc. | Ensures product consistency |

| Voltage: ±0.01V, Internal Resistance: ±0.1mΩ | High-precision inspection equipment | |

| Environmental Requirements | Operating Temperature | 10-25ºC |

| Relative Humidity | 40-60% | |

| Power Supply | 380V±10%, 50Hz | |

| Air Source Requirement | Compressed air pressure 0.5~0.7MPa | |

| Delivery Lead Time | 1-2 months | From contract signing to delivery |

| After-Sales Service | Warranty Period | 2 year |

| Installation and Debugging | Installation, debugging, and operator training provided | |

| Response Time | 24-hour response |

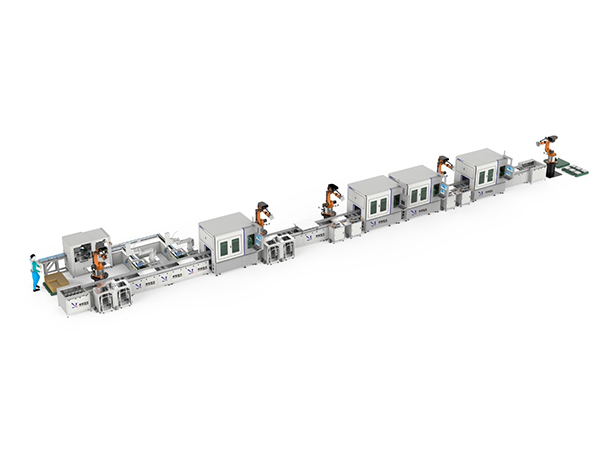

A Pouch Battery Module Pack Assembly Line is a fully automated production system that integrates pouch battery cells into complete modules and packs. Unlike manual or semi-automated methods, our assembly line ensures:

High precision in cell alignment and stacking

Consistent weld quality for optimal electrical conductivity

Efficient throughput for mass production

Minimal human intervention, reducing error risks

This system is critical for meeting the growing demand for reliable, high-performance prismatic battery solutions in EVs and energy storage.

Why Choose Our Pouch Battery Assembly Line?

High-Speed Automation

Robotic cell handling, stacking, and welding for maximum efficiency.

Reduced cycle time with synchronized conveyor systems.

Precision Engineering

Laser-guided alignment for accurate cell positioning.

Adaptive welding technology for strong, defect-free connections.

Scalable & Flexible

Modular design allows easy upgrades for higher capacity or new cell formats.

Compatible with various prismatic cell sizes and chemistries.

Smart Quality Control

Real-time monitoring with AI-powered defect detection.

Automated rejection of faulty modules to ensure 100% reliability.

Huiyao Laser Pouch Battery Module Pack Assembly Lines incorporate advanced technologies:

High Automation: Fully automated assembly equipment reduces manual intervention and improves production efficiency.

Applications

1. Electric Vehicles (EVs):

• Electric cars (especially in hybrid or compact EVs)

• Electric motorcycles and scooters

• E-bikes and e-skateboards

2. Energy Storage Systems (ESS):

• Home solar energy storage (e.g., wall-mounted batteries)

• Grid-level or commercial backup systems

3. Drones and UAVs

• Lightweight and high-energy drone batteries

• Military or commercial aerial systems

Pouch Battery Module PACK Assembly Line Supplier

The transition to clean energy and electrified transportation is accelerating the global demand for efficient battery solutions. Battery Module PACK Assembly Line, especially those from Huiyao Laser, offer the advanced capabilities needed to meet this demand. By investing in laser welding technology, manufacturers can ensure faster production, better product quality, and a competitive edge in the market.

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Pouch Battery Module PACK Line

EV Blade Battery Module PACK Line

EV Prismatic Battery CTP Automatic Welding Line

EV Blade Battery CTP Automatic Welding Line

ESS Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Lines

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.