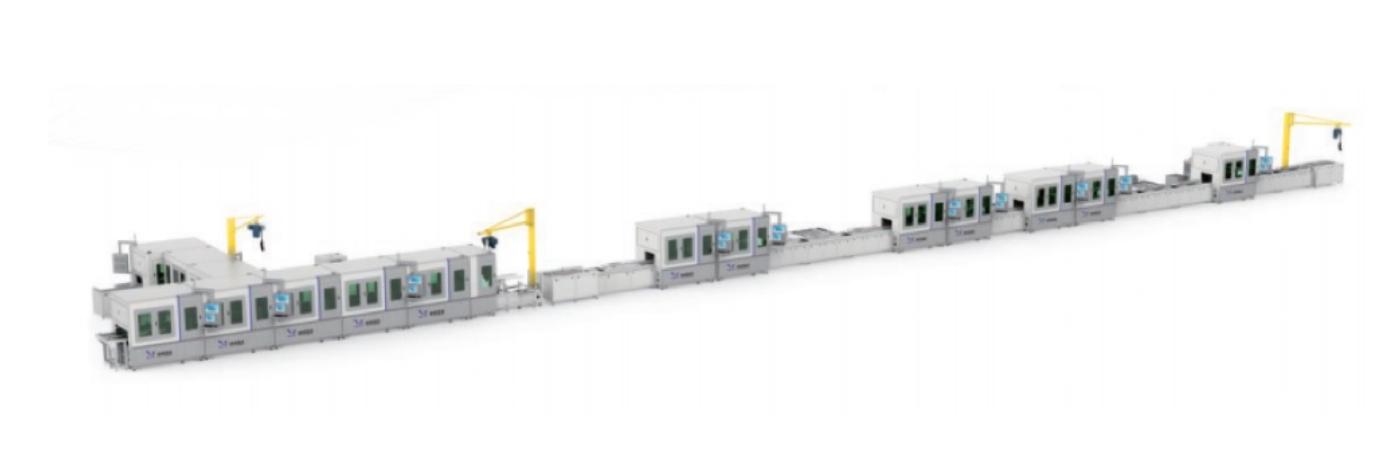

Turnkey Solution for New Energy Intelligent Equipment

As the demand for lightweight, high-energy, and safe energy storage solutions grows, pouch cell battery modules are gaining significant attention across the electric vehicle, energy storage, and consumer electronics industries. Unlike cylindrical or prismatic cells, pouch cells offer superior energy density and design flexibility, but also pose unique challenges in assembly due to their soft structure and stringent sealing requirements.

This article explores how next-generation pouch cell module production lines, powered by technologies like laser welding, AI inspection, and modular automation, are shaping the future of energy manufacturing — with HuiyaoLaser playing a key role in precision joining and intelligent integration.

1. Why Pouch Cells?

Pouch cells are thin, lightweight, and highly customizable in size and shape. They offer:

However, their flexible packaging requires non-destructive handling, high-precision sealing, and stable structure reinforcement, all of which demand advanced production solutions.

2. Full-Process Integration for Pouch Module Assembly

Modern pouch cell module production lines are designed to handle the entire process flow, including:

Cell Sorting & Stacking

Automated sorting ensures consistency in cell quality. High-speed stacking aligns cells with tight tolerances to prepare them for tab welding and encapsulation.

Laser Tab Welding

This is a core process where HuiyaoLaser’s precision laser welding systems shine. Their high-accuracy, low-thermal-impact welding enables:

Insulation, Frame, and Structural Assembly

Module Sealing and Enclosure

The assembled cells are placed into module housings, sealed with adhesives or laser-welded covers, ensuring:

Intelligent Inspection

Functional Testing & Data Traceability

3. Key Advantages of the Modern Pouch Module Line

4. Application Scenarios

5. HuiyaoLaser: Empowering Precision & Intelligence

As a specialist in laser welding and intelligent manufacturing systems, HuiyaoLaser (Luoyang) Technology Co., Ltd. provides core solutions for pouch module production, including:

By integrating AI, machine vision, and digital control, HuiyaoLaser helps battery manufacturers achieve higher yield, improved safety, and scalable smart production.

Conclusion

The pouch battery module production line is a cornerstone of modern energy manufacturing, enabling the delivery of lightweight, safe, and high-performance batteries across multiple industries.With innovations in laser processing and AI-driven inspection, HuiyaoLaser is driving the intelligent transformation of pouch cell assembly lines, making battery production faster, smarter, and more sustainable.

About HuiyaoLaser

HuiyaoLaser (Luoyang) Technology Co., Ltd. is a trusted partner in intelligent laser processing solutions, specializing in laser welding systems for battery module and PACK lines. With a strong focus on automation, precision control, and AI-driven visual inspection, HuiyaoLaser supports global manufacturers in achieving higher quality, lower cost, and safer production.

Whether enabling ultra-high-speed lines or facilitating solid-state battery innovation, HuiyaoLaser is committed to empowering the future of energy through laser intelligence.

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.