Turnkey Solution for New Energy Intelligent Equipment

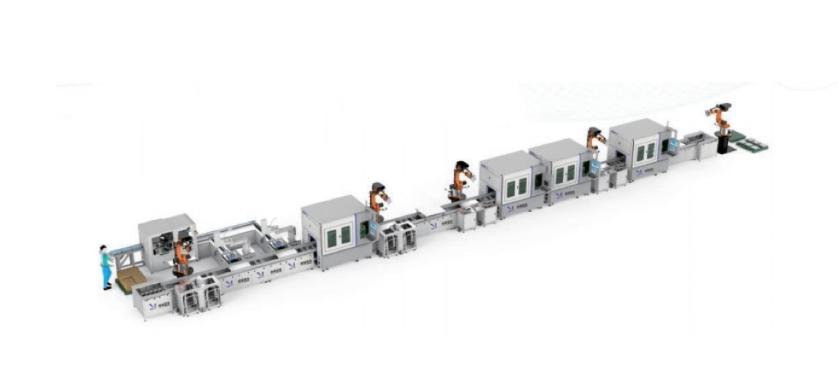

With the deep integration of new energy and smart manufacturing, cylindrical battery module assembly lines are entering a new era characterized by higher speed, precision, and flexibility. Leading manufacturers are now leveraging advanced process innovations and intelligent technologies to create highly efficient, fully integrated, and sustainable production lines.

The traditional bottleneck in module production efficiency has been broken. Next-generation lines can achieve a throughput of over 20 modules per minute (20 PPM), significantly enhancing output capacity.

For example, Lead Intelligent’s "All-Tab Cylindrical Assembly Line" optimizes process flow and equipment synergy to reduce footprint by 53% and cut energy consumption by 33%, setting a new industry standard for efficiency.

These advanced lines integrate the entire manufacturing process—from cell sorting and laser welding to module packaging and automated testing—and support multiple cylindrical cell formats including 18650, 21700, and 4680.

HuiyaoLaser’s advanced laser welding solutions are deeply embedded in this stage, ensuring precise, high-strength joints critical to modern cylindrical modules.

A modular design enables rapid line reconfiguration to adapt to different customer product needs, ensuring maximum flexibility and scalability.

Combining full-space 3D vision with AI-powered defect detection, the system conducts real-time analysis of weld quality, detects surface defects such as pores and cracks, and ensures module flatness.

HuiyaoLaser integrates intelligent visual inspection and adaptive control into its laser processing systems, enabling continuous self-optimization and enhancing production stability.

Equipped with an MES (Manufacturing Execution System), the line provides full traceability of production parameters. Digital twin technology is used to simulate and optimize production line design, dramatically reducing time-to-production and improving operational efficiency.

Ultra-fast cycle times reduce labor and unit manufacturing costs while maximizing equipment utilization.

Example: Huaguan Technology’s third-generation assembly line adopts a cam + turret mechanism, achieving high-speed and high-stability operation.

Application

Key Benefits

Electric Vehicles (EVs)

High-energy-density modules for long-range and safety-focused EVs

Energy Storage Systems (ESS)

Ideal for grid-scale wind and solar storage, improving integration and cost efficiency

Consumer Electronics

Compact, lightweight modules for power tools and wearables with fast-charging and high-output performance

Case Highlight: EVE Energy’s large cylindrical cells demonstrate high-frequency output and strong safety in drones and robotic applications.

HuiyaoLaser (Luoyang) Technology Co., Ltd. is a trusted partner in intelligent laser processing solutions, specializing in laser welding systems for battery module and PACK lines. With a strong focus on automation, precision control, and AI-driven visual inspection, HuiyaoLaser supports global manufacturers in achieving higher quality, lower cost, and safer production.

Whether enabling ultra-high-speed lines or facilitating solid-state battery innovation, HuiyaoLaser is committed to empowering the future of energy through laser intelligence.

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.