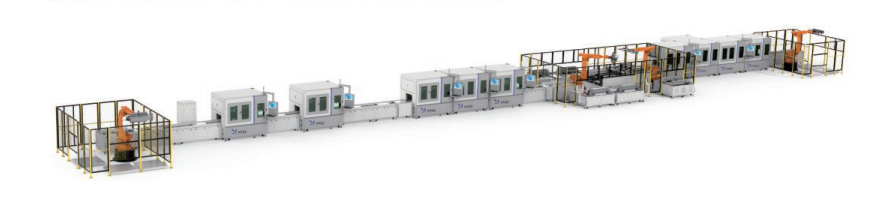

As the demand for residential energy storage solutions grows, the need for smart, adaptable manufacturing becomes more critical. HuiYao Laser (LuoYang) Technology Co., Ltd. has developed a cutting-edge flexible Pack production line for household energy storage systems. Featuring modular design, intelligent control, and high compatibility, this production line dramatically boosts efficiency and adaptability—making it ideal for today’s rapidly evolving energy market.

Key Advantages

1. Modular Architecture for Flexible Production

The production line adopts a modular structure, where each unit can operate independently or be flexibly integrated with others. This design allows quick adjustment of process parameters to accommodate various Pack sizes and configurations. The modularity also makes it easier for manufacturers to respond swiftly to changes in demand—offering both scalability and flexibility.

2. Intelligent Control with Real-Time Optimization

Huiyao Laser’s system is equipped with advanced intelligent control software that monitors and adjusts production in real-time. For example, machine learning algorithms are used to optimize welding parameters for consistent quality, while digital twin technology enables virtual commissioning, reducing setup time and improving fault prediction accuracy.

3. High Compatibility with Multiple Cell Types

This line supports multiple cell formats and module specifications. For modules using the same cell model but in different quantities, operators only need to adjust a few fixture points. This changeover process usually takes less than 4 hours, ensuring minimal downtime and maximum responsiveness to market needs.

Core Technologies

Fast Line Change Capability

Thanks to its modular design and standardized interfaces, the line supports quick switching between different products. This significantly reduces preparation time and enables multi-model production with higher efficiency.

Precision Manufacturing Techniques

The line employs a CCD visual alignment system to position battery tabs with an accuracy of ±0.1 mm, ensuring superior weld quality. In addition, a constant-force stacking system (5 ± 0.2 N) prevents cell damage. These high-precision processes ensure consistency and reliability in Pack assembly.

Eco-Friendly and Safe Design

Safety and environmental standards are central to Huiyao Laser’s design. Each welding area is enclosed with safety shields and automatic doors to protect operators. A sealed laser room combined with a smoke purification system captures and filters hazardous fumes, fully compliant with environmental regulations.

Applications and Benefits

Customized Production for Diverse Needs

The flexible production line easily adapts to client-specific requirements, including different capacities, voltages, and sizes. This allows manufacturers to customize products without major production changes, increasing market competitiveness.

Boosted Efficiency

Automation and intelligent systems significantly improve throughput. For example, production efficiency can reach 12–16 PPM (cells per minute) with a first-pass yield above 99.3%.

Lower Operational Costs

Key Advantages

1. Modular Architecture for Flexible Production

The production line adopts a modular structure, where each unit can operate independently or be flexibly integrated with others. This design allows quick adjustment of process parameters to accommodate various Pack sizes and configurations. The modularity also makes it easier for manufacturers to respond swiftly to changes in demand—offering both scalability and flexibility.

2. Intelligent Control with Real-Time Optimization

Huiyao Laser’s system is equipped with advanced intelligent control software that monitors and adjusts production in real-time. For example, machine learning algorithms are used to optimize welding parameters for consistent quality, while digital twin technology enables virtual commissioning, reducing setup time and improving fault prediction accuracy.

3. High Compatibility with Multiple Cell Types

This line supports multiple cell formats and module specifications. For modules using the same cell model but in different quantities, operators only need to adjust a few fixture points. This changeover process usually takes less than 4 hours, ensuring minimal downtime and maximum responsiveness to market needs.

Core Technologies

Fast Line Change Capability

Thanks to its modular design and standardized interfaces, the line supports quick switching between different products. This significantly reduces preparation time and enables multi-model production with higher efficiency.

Precision Manufacturing Techniques

The line employs a CCD visual alignment system to position battery tabs with an accuracy of ±0.1 mm, ensuring superior weld quality. In addition, a constant-force stacking system (5 ± 0.2 N) prevents cell damage. These high-precision processes ensure consistency and reliability in Pack assembly.

Eco-Friendly and Safe Design

Safety and environmental standards are central to Huiyao Laser’s design. Each welding area is enclosed with safety shields and automatic doors to protect operators. A sealed laser room combined with a smoke purification system captures and filters hazardous fumes, fully compliant with environmental regulations.

Applications and Benefits

Customized Production for Diverse Needs

The flexible production line easily adapts to client-specific requirements, including different capacities, voltages, and sizes. This allows manufacturers to customize products without major production changes, increasing market competitiveness.

Boosted Efficiency

Automation and intelligent systems significantly improve throughput. For example, production efficiency can reach 12–16 PPM (cells per minute) with a first-pass yield above 99.3%.

Lower Operational Costs

By reducing manual intervention and material waste, the system lowers overall production costs. Optimized workflows and high equipment uptime (over 98%) contribute to improved economic performance and faster return on investment.

HuiYao Laser Technology (Luoyang)Co.,Ltd.(AKA YaoLaser)

Leading manufacturer of new energy intelligent equipment in the industry, dedicated to providing innovative customized solutions for Battery Module PACK Assembly Lines across various sectors. Since our establishment in 2019, Huiyao Laser has been consistently driving the development and application of laser technology, offering our customers high-quality, high-performance laser equipment, and automation production lines for battery module PACK assembly. If you are interested in us, please contact us;