Turnkey Solution for New Energy Intelligent Equipment

Laser welding machines play a crucial role in the aerospace industry, where precision, reliability, and high-quality welds are essential. They are used for a wide range of applications, from joining intricate components to repairing critical parts. Here are some important points to consider regarding laser welding machines in the aerospace industry:

Materials and Components: The aerospace industry works with various materials, including aluminum, titanium, stainless steel, and exotic alloys. Laser welding machines are capable of welding these materials, making them suitable for aerospace applications. They are used to join components such as aircraft fuselages, engine parts, turbine blades, fuel systems, and structural elements.

Precision and Consistency: Laser welding machines offer precise control over the welding process, enabling consistent and repeatable results. The focused laser beam allows for accurate energy deposition and control of the weld pool, ensuring tight tolerances and minimizing distortion.

High Strength and Quality: Laser welding produces high-quality welds with excellent mechanical properties. The process results in minimal heat-affected zones, reducing the risk of metallurgical issues and maintaining the material's strength. This is crucial for aerospace components that need to withstand extreme conditions and ensure the safety of aircraft and spacecraft.

Non-contact Welding: Laser welding is a non-contact process, meaning there is no physical contact between the laser and the workpiece. This eliminates the risk of contamination or damage to delicate aerospace components. It also allows for easier access to complex or hard-to-reach areas, making laser welding suitable for intricate aerospace parts.

Weld Repair and Refurbishment: Laser welding machines are utilized in the aerospace industry for repair and refurbishment purposes. They can restore damaged components, repair cracks or defects, and extend the lifespan of critical parts. Laser welding's localized heat input minimizes the impact on the surrounding material, enabling precise repairs with minimal distortion.

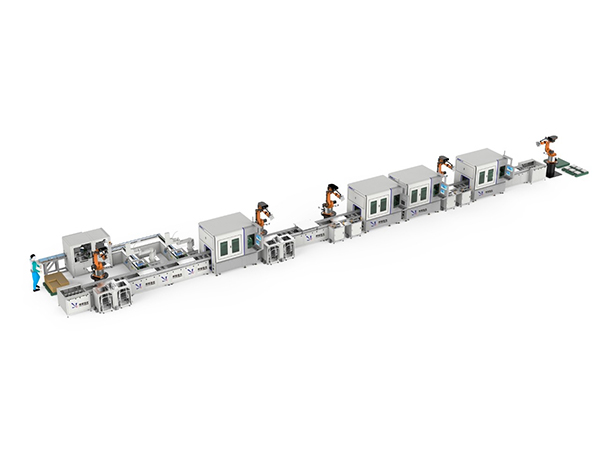

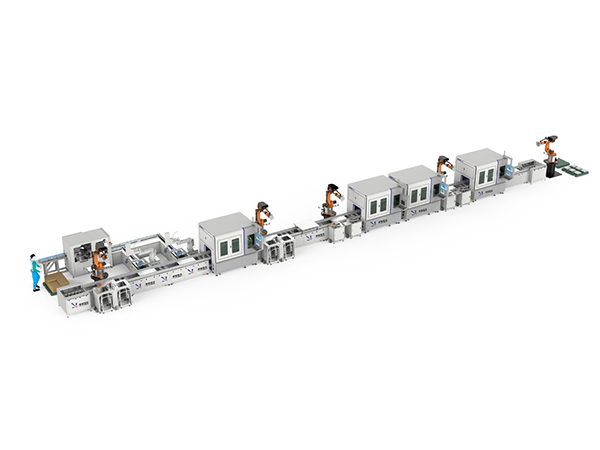

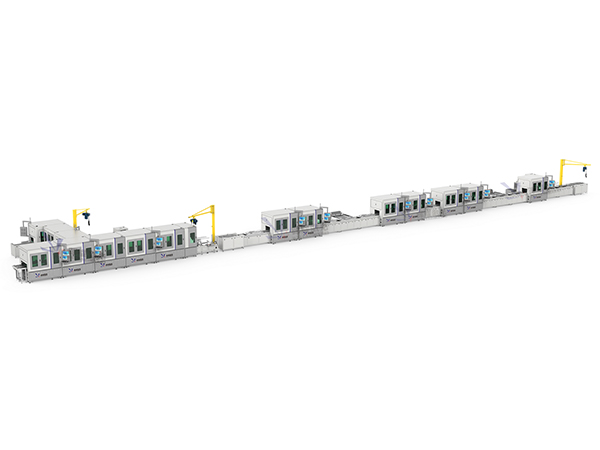

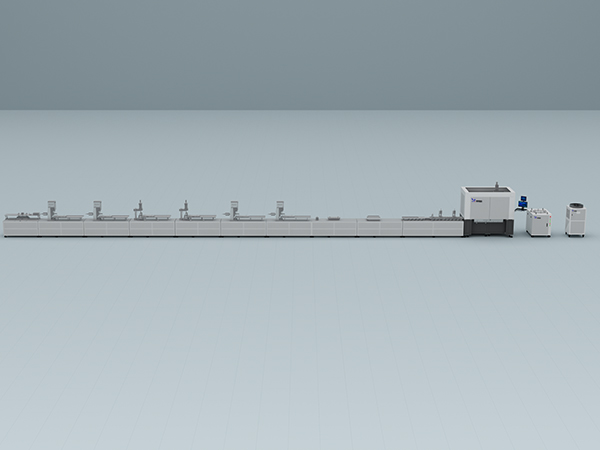

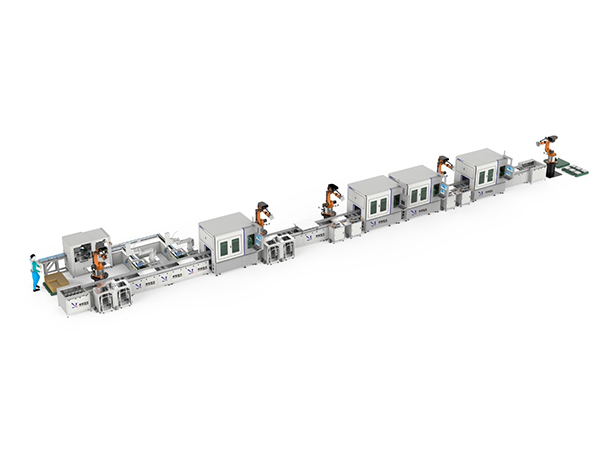

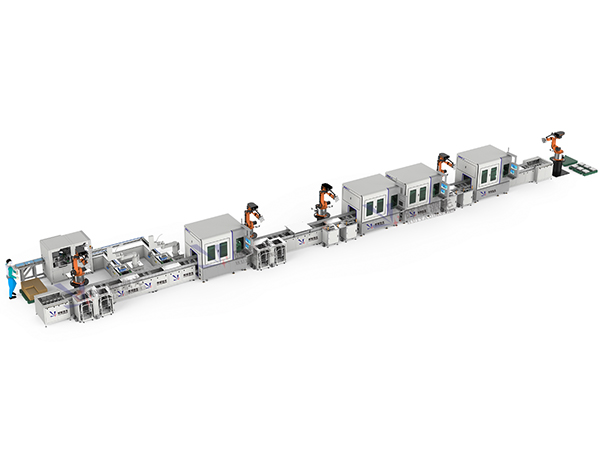

Automation and Integration: Laser welding machines can be integrated into automated production lines, enhancing productivity and efficiency in aerospace manufacturing processes. They can be seamlessly integrated with robotics, CNC machining systems, or other automation equipment, allowing for a streamlined production workflow.

Quality Control and Inspection: Laser welding machines often incorporate advanced monitoring and inspection systems to ensure weld quality and detect potential defects. These systems may include real-time monitoring of parameters such as temperature, energy input, and weld penetration, as well as non-destructive testing techniques for quality assurance.

Compliance with Aerospace Standards: Laser welding machines used in the aerospace industry must adhere to strict quality standards and certifications. They should comply with industry-specific regulations, such as those set by organizations like the Federal Aviation Administration (FAA) or the European Aviation Safety Agency (EASA).

When selecting a laser welding machine for aerospace applications, factors such as power output, beam quality, automation capabilities, and compliance with industry standards should be considered. It is advisable to consult with suppliers or manufacturers experienced in providing laser welding solutions for the aerospace industry to ensure the chosen machine meets the specific requirements and quality standards of aerospace applications.

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Pouch Battery Module PACK Line

EV Blade Battery Module PACK Line

EV Cylindrical Battery Module PACK Assembly Lines

Prismatic Battery Cap Manufacture Line

Cylindrical Battery Manufacture Line

Pouch Battery Module Pack Assembly Line

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.