Turnkey Solution for New Energy Intelligent Equipment

In the automotive industry, laser welding machines are mainly used in the following aspects:

Laser brazing for car roofs: In the programming and welding practice of robot car roof welding, the key lies in determining the size and relative position of the focal point. As shown in Figure 4, the cone represents the incident laser, the spot represents the laser focal point on the welding seam surface, and the two overlapping shaded blocks represent the car roof and side panel parts to be welded. By adjusting the distance L between the focusing lens group and the welding seam, the size of the focal point can be changed, and adjusting the left-right distance can determine the focal point's position relative to the car roof and side panel. In the practical programming and welding of car roofs, it is found that the key lies in determining the size and relative position of the focal point. As shown in Figure 4, the spot represents the laser focal point on the welding seam surface, the cone represents the incident laser, and the two shaded blocks overlapping each other represent the car roof and side panel parts to be welded. By adjusting the vertical distance L between the welding seam and the focusing lens group, the size of the focal point can be changed, and adjusting the left-right distance can determine the focal point's position on the car roof and side panel.

Laser lap welding: Laser lap welding is one of the main materials in the automotive industry and an extension product of the steel industry. It holds a high position in the automotive manufacturing and steel industries. Laser lap welding involves "cutting" steel plates of different materials, strengths, and thicknesses into appropriately sized blanks, which are then welded into stamped sheets. Using laser lap welding technology can reduce component weight, save material consumption, reduce process and assembly workload, lower costs, improve the accuracy of vehicle dimensions, reduce part tolerances, and enhance overall structural rigidity and safety. It allows for the full utilization of steel. Figures 5 and 6 respectively show the production line for laser lap welding and processed parts.

Laser brazing for trunk lids: Figure 7 shows the direction of the weld seam on the trunk lid, where the positions of the two "uphill" and "downhill" slopes pose challenges in robot posture control. It is relatively easy for the robot to experience jitter during movement, which can affect wire feeding stability or lead to shrinkage, false welding, weld bead accumulation, or other welding defects.

Other component laser welding applications.

To improve vehicle smoothness and comfort, most modern automobiles (especially sedans) are equipped with suspension systems that primarily use hydraulic shock absorbers. Twin-tube shock absorbers are commonly used due to their stable performance, lightweight, and reliable operation. The oil storage cylinder of the shock absorber is often subjected to high pressure during use, requiring excellent air tightness and resistance to tensile fracture.

Laser welding technology has had a significant impact on the traditional automotive manufacturing industry. In the fiercely competitive automotive industry, adopting new technologies means having a stronger competitive edge. Therefore, major car companies have a very positive attitude towards laser welding technology. In this regard, laser manufacturers should seize the business opportunities and improve and optimize laser devices in terms of size, optoelectronic conversion, mobility, etc., to better meet the needs of automotive production lines. Our company's handheld fiber laser welding machine is user-friendly, with stable and reliable laser performance and long service life. It can also be combined with welding robots to form a fully automated welding workstation, improving production efficiency and reducing costs. The pulsed laser welding machine supports multiple outputs and can simultaneously complete laser welding for different processes, making it versatile and especially suitable for laser processing workshops and automated production lines.

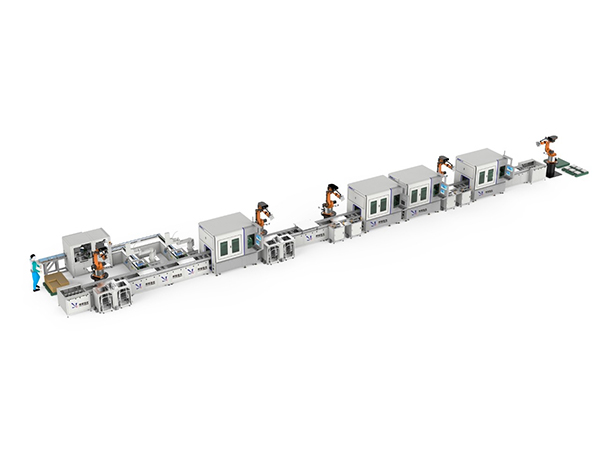

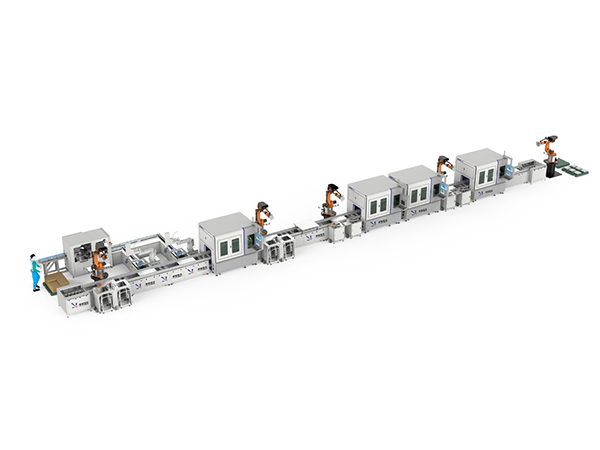

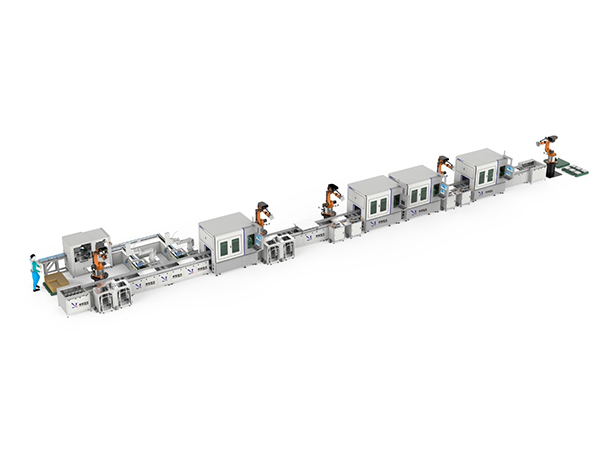

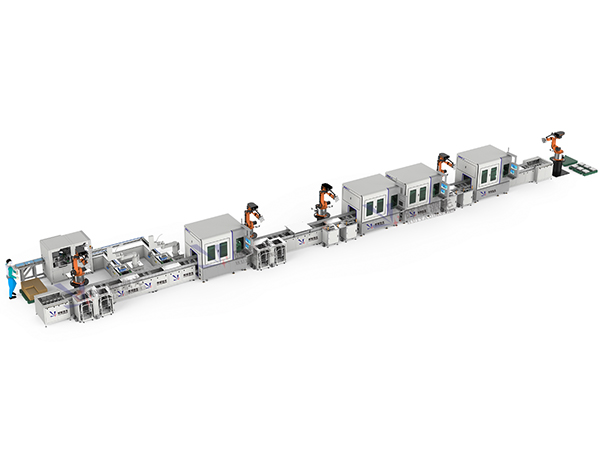

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Pouch Battery Module PACK Line

EV Blade Battery Module PACK Line

EV Cylindrical Battery Module PACK Assembly Lines

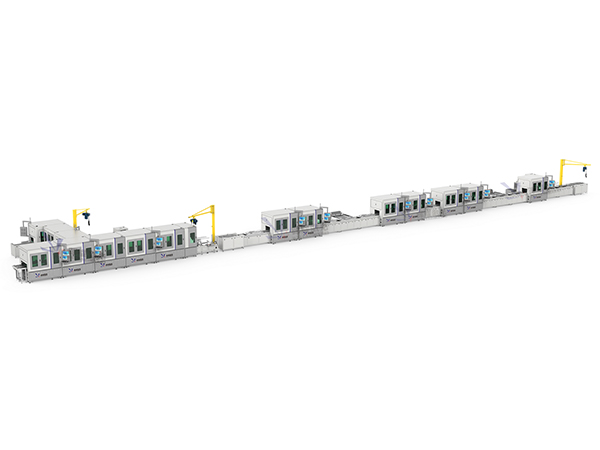

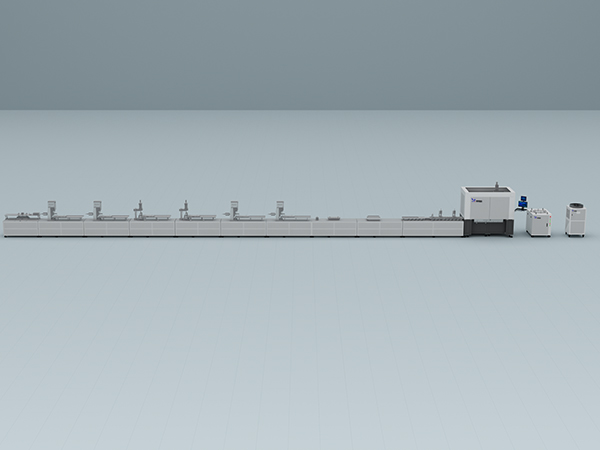

Prismatic Battery Cap Manufacture Line

Cylindrical Battery Manufacture Line

Pouch Battery Module Pack Assembly Line

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.