Turnkey Solution for New Energy Intelligent Equipment

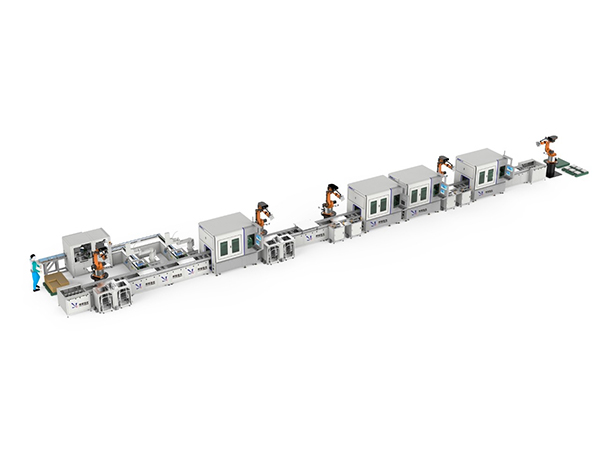

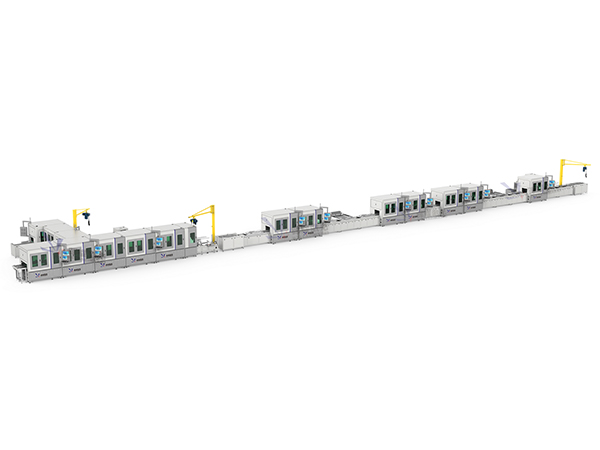

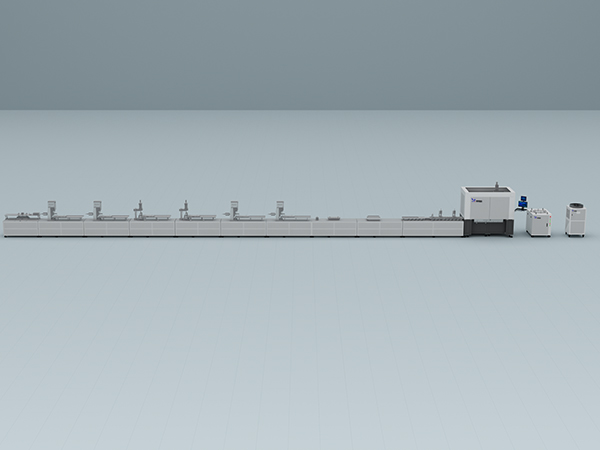

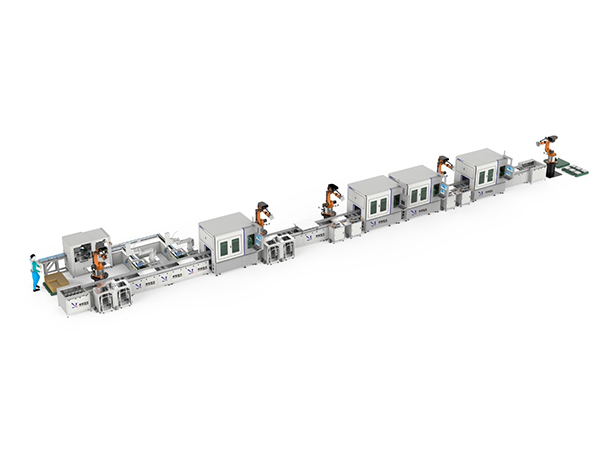

The EV Prismatic Battery CTP (Cell-to-Pack) Automatic Welding Line is a high-performance, fully automated production line for assembling prismatic cells directly into battery packs without using traditional modules. The system integrates advanced welding technologies, precision handling, and quality inspection processes to ensure structural integrity and electrical performance. Designed for large-scale EV battery manufacturing, it enables efficient, scalable, and cost-effective production.

Categories: Lithium Battery PACK Assembly REQUEST FOR QUOTE > TURN BACKThe EV Prismatic Battery CTP (Cell-to-Pack) Automatic Welding Line is a high-performance, fully automated production line for assembling prismatic cells directly into battery packs without using traditional modules. The system integrates advanced welding technologies, precision handling, and quality inspection processes to ensure structural integrity and electrical performance. Designed for large-scale EV battery manufacturing, it enables efficient, scalable, and cost-effective production.

2.1 Automatic Cell Feeding and Positioning Station

Function: Automatically feeds and positions prismatic cells for alignment and welding.

Specifications:

Cell Size Compatibility: 120–600 mm (height), 50–150 mm (width), 20–50 mm (thickness).

Positioning Accuracy: ±0.2 mm.

Cycle Time: ≤10 seconds per cell.

2.2 Cell-to-Busbar Welding Station

Function: Welds the terminals of prismatic cells to the pack's busbars.

Specifications:

Welding Method: Fiber laser or ultrasonic welding.

Welding Power: 600–1,500 W (adjustable).

Welding Speed: ≤5 seconds per weld.

Welding Accuracy: ±0.05 mm.

Quality Control: Real-time weld monitoring with automatic defect detection.

2.3 Cooling Plate Integration and TIM Application Station

Function: Installs cooling plates and applies thermal interface material (TIM) for heat dissipation.

Specifications:

TIM Application Accuracy: ±0.1 mm.

Cooling Plate Types: Liquid or air-cooled aluminum plates.

Cycle Time: ≤20 seconds per assembly.

2.4 Structural Bonding and Fastening Station

Function: Bonds and fastens cells and supporting structures to enhance mechanical stability.

Specifications:

Adhesive Type: High-strength epoxy or UV-curable adhesive.

Bonding Accuracy: ±0.2 mm.

Fastening Type: Automated torque-controlled screws.

2.5 High-Voltage Connector and Harness Assembly Station

Function: Assembles and connects high-voltage terminals, connectors, and harnesses for the battery pack.

Specifications:

Voltage Range: ≤1,000V DC.

Assembly Accuracy: ±0.3 mm.

Cycle Time: ≤30 seconds per connection.

2.6 Final Welding and Sealing Station

Function: Performs final welding of pack enclosures and seals for protection against environmental factors.

Specifications:

Welding Type: Laser seam welding.

Sealing Material: Silicone or polymer-based gasket.

Weld Accuracy: ±0.1 mm.

2.7 Electrical Testing and Quality Inspection Station

Function: Tests the electrical integrity, insulation, and performance of the assembled battery pack.

Specifications:

Test Parameters: Voltage, internal resistance, insulation resistance, and leakage current.

Testing Speed: ≤3 minutes per PACK.

Helium Leak Detection Sensitivity: ≤1x10⁻⁶ Pa·m³/s.

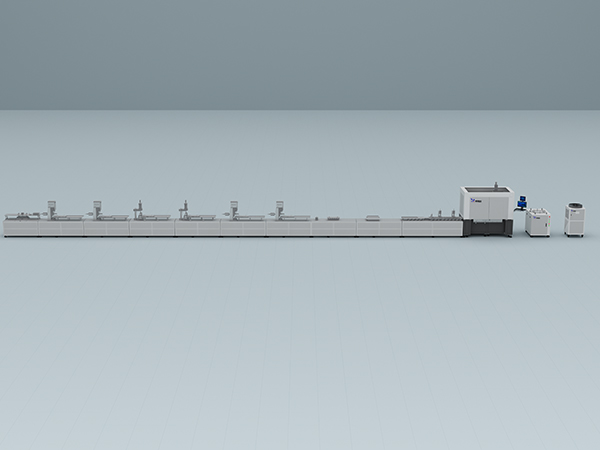

Overall Dimensions:

Length: 80,000 mm.

Width: 12,000 mm.

Height: 4,000 mm.

Weight: Approximately 50,000 kg.

Production Capacity: 10–15 PACKs/hour.

Automation Level: Fully automated with robotic systems and AI-driven quality control.

Alignment Cameras:

Resolution: 8 MP industrial cameras.

Alignment Accuracy: ±0.05 mm.

Defect Detection: AI-based system for surface, weld, and assembly defect detection.

Data Management: All inspection results stored in a centralized database with traceability.

Control System: Distributed PLC system with centralized supervision.

Human-Machine Interface (HMI):

17-inch touchscreen interface with multi-language support.

Real-time monitoring and diagnostic tools.

IoT Integration: Remote monitoring, predictive maintenance, and cloud data storage for production analytics.

Enclosure Design: Fully enclosed with interlocked safety doors and barriers.

Emergency Stop System: Strategically placed for operator safety.

Laser Safety: Class 1 laser enclosures with safety interlocks.

Electrical Safety: Overcurrent and surge protection included.

Power Supply: AC 380V ±10%, 50/60 Hz, 3-phase.

Maximum Power Consumption: 300 kW.

Control Voltage: 24V DC for auxiliary systems.

Type: Centralized water cooling system for welding and high-power equipment.

Cooling Capacity: 120 kW.

Flow Rate: 30–60 L/min.

Operating Environment:

Temperature: 15–30°C.

Humidity: ≤60% RH (non-condensing).

Noise Level: ≤75 dB during operation.

Installation Space: Minimum clearance of 2,000 mm around the line.

Maintenance Schedule:

Weekly: Inspect alignment, welding, and cooling systems.

Monthly: Calibrate vision systems and test stations.

Quarterly: Comprehensive diagnostics and software updates.

Warranty Period:

Standard: 12 months.

Extended: Available upon request.

Pouch Battery Module Pack Assembly Line

EV Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Line

EV Pouch Battery Module PACK Line

EV Blade Battery Module PACK Line

EV Blade Battery CTP Automatic Welding Line

ESS Prismatic Battery Module PACK Assembly Line

EV Cylindrical Battery Module PACK Assembly Lines

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.