Turnkey Solution for New Energy Intelligent Equipment

Equipment Dimensions: Length: 1500 mm Width: 1200 mm Height: 1800 mm Weight: 1100 kg ± 5% Frame Material: High-strength steel frame with anti-corrosion coating. Worktable Material: Anodized aluminum with anti-static and wear-resistant surface. Wrapping Mechanism: Servo-driven rollers with precision tension control.

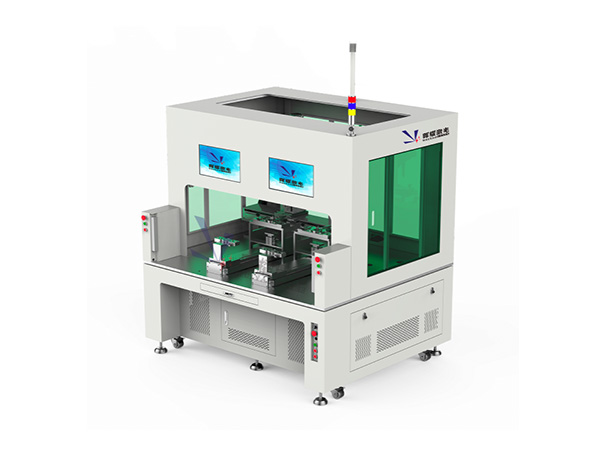

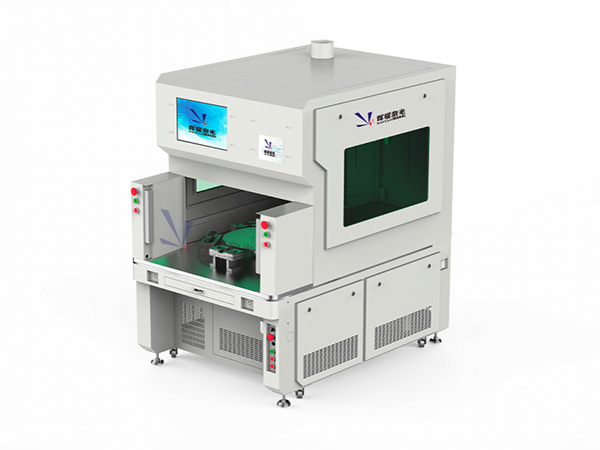

Categories: Laser Welding Machine REQUEST FOR QUOTE > TURN BACKEquipment Name: Battery Mylar Film Wrapping Equipment

Model: HY-MFW7070

Application: Precise wrapping of Mylar insulation film around battery cells for enhanced safety and electrical isolation in prismatic, cylindrical, and pouch batteries.

Equipment Dimensions:

Length: 1500 mm

Width: 1200 mm

Height: 1800 mm

Weight: 1100 kg ± 5%

Frame Material: High-strength steel frame with anti-corrosion coating.

Worktable Material: Anodized aluminum with anti-static and wear-resistant surface.

Wrapping Mechanism: Servo-driven rollers with precision tension control.

Film Material: Mylar, PET, or other insulation films.

Film Thickness Range: 0.02–0.1 mm.

Cell Size Compatibility:

Width: 50–200 mm.

Height: 50–400 mm.

Thickness: 5–50 mm.

Wrapping Speed: Up to 15 cells per minute (process-dependent).

Film Overlap Control: 2–5 mm (programmable).

Cutting Mechanism: Servo-driven cutter with ±0.1 mm accuracy.

Adhesive Application (Optional): Integrated hot-melt or pressure-sensitive adhesive system for film sealing.

Alignment Accuracy: ±0.05 mm.Camera Specifications:

Resolution: 5 MP industrial-grade CCD camera.

Field of View: Adjustable for various cell sizes.

Lighting: Diffused LED lighting for clear film edge detection.

Inspection Features:

Detection of wrinkles, overlaps, and film misalignment.

Monitoring of film tension and cutting precision.

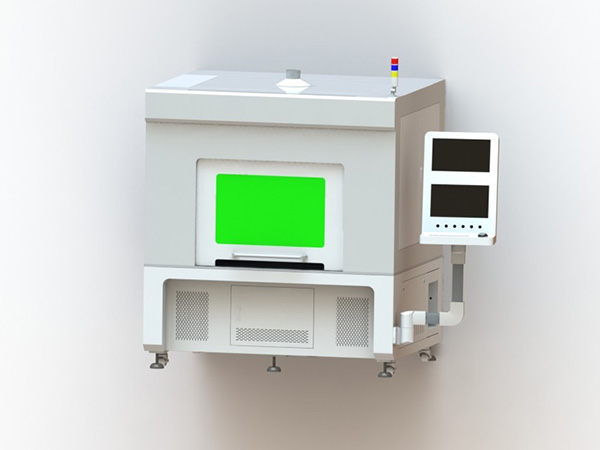

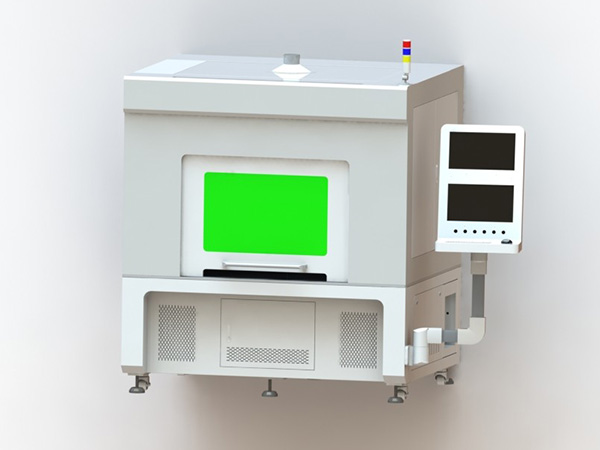

Control System: PLC with integrated HMI for real-time operation.

Interface:

10-inch capacitive touchscreen.

Multi-language support (English, Chinese, others).

Programmable Parameters:

Film tension, overlap, and wrapping speed.

Cutting length and sealing temperature.

Recipe storage for different battery configurations.

Data Logging:

Internal Capacity: 500 GB for process history.

Export Formats: CSV via USB, Ethernet, or Wi-Fi.

Power Supply: AC 220V ± 10%, 50/60 Hz, single-phase.

Maximum Power Consumption: 4 kW.

Control Voltage: 24V DC for auxiliary systems.

Emergency Stop: Dual emergency stop buttons on the front and rear panels.

Film Tension Monitoring: Automatic halt on over-tension or film breakage.

Protective Enclosure: Transparent cover with interlock mechanism.

Thermal Safety: Overheat protection for sealing and adhesive systems.

Operating Environment:

Temperature: 10–30°C

Humidity: ≤65% RH (non-condensing).

Noise Level: ≤70 dB during operation.

Installation Requirements:

Flat and vibration-free surface.

Clearance: Minimum 600 mm on all sides.

Dual Film Feeding System: For continuous operation without downtime.

Integrated Pre-Wrap Cleaning Module: Ionized air cleaning to remove dust and debris from battery surfaces.

Customized Wrapping Profiles: For non-standard battery dimensions or shapes.

IoT Connectivity: Cloud-based monitoring and predictive maintenance.

Maintenance Schedule:

Weekly: Clean film feeding rollers and cutter.

Monthly: Inspect servo motors and alignment systems.

Quarterly: Calibrate sensors and lubricate moving parts.

Warranty Period:

Standard: 12 months.

Extended: Up to 36 months available upon request.

Battery Laser Welding Machine

Dual-Station Terminal Pole Welding Machine

Six-Station Rotary Welding Machine

Automatic Explosion-Proof Valve Welding Machine

Dual-Station Enclosed Rotary Welding Machine

Battery Terminal Tab Welding Equipment

Battery Terminal Tab Ultrasonic Welding Equipment

Battery Terminal Tab Transition Sheet Welding Equipment

Email: yaolaser@huiyaolaser.com

Head Quarter Address: Huiyao Laser Technology, Building 2, Langxu Industrial Park, Guanlin Road, Science Park Street, Luolong District, Luoyang City, Henan Province, China

Research&Development Center: Room 901-9,Building B1, Phase 1, Southern Area, Baoneng Science and Technology Park, Qinghu Industrial Zone, Gangtou Community, Batian Street, Longgang District, Shenzhen City.